Overview

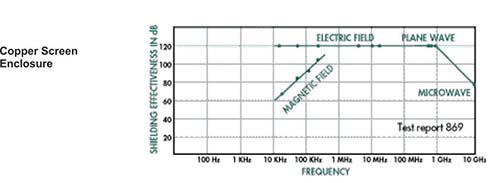

ETS-Lindgren's standard modular or custom DEI screen industrial shielding enclosures provide the highest shielding performance available in a "hear-through, see-through" structure. These copper screen enclosures are used where absence of a sense of confinement or where casual observation from the outside is desirable. The superior shielding characteristics obtained from ETS-Lindgren screen enclosures are primarily the result of DEI construction, which permits screen to be used where solid double shield construction would ordinarily be used.

In some applications, screen enclosures eliminate the need for additional ventilation. Where required, exhaust fans or connections to existing air handling systems are easily added. Screen rooms are very easy to assemble because of the inherent flexibility of the shielding material which requires lower clamping pressures than are generally required with steel and other rigid materials.

Kick-plates or protective paneling are used to protect the lower 81.28 cm (32 in) on the inside and outside of each wall panel. Kick-plates are made of an attractive wood grain paneling. A color coordinated vinyl tile is installed over 1.9 cm (.75 in) plywood panels which are connected with .317 cm (.125 in) thick, 10.16 cm (4 in) wide aluminum strips to provide an entirely flush modular floor system.

Materials

A heavier 55.88 cm x 55.88 cm x .038 cm (22 in x 22 in x .015 in) copper wire mesh is offered for applications which require the advantages of screen, with the best possible high frequency microwave and improved low frequency magnetic attenuation characteristics.

Doors

The DEI door employs a number of unique proprietary and patented features which contribute to its superior performance characteristics and durability. All hardware and door seals are designed to maintain electrical isolation between the inner and outer shields. Doors are side hinged and supported by three heavy duty hinges to provide sag-free mounting and have been cycle tested up to 25,000 operations.

A three-point roller bearing latching system applies uniform pressure to two sets of spring temper phosphor bronze contact fingers to provide leak-proof seals for both the inner and outer shields.

The three-point clamping system draws the door into a closed position when the 71.12 cm (28 in) panic type handle is pulled up with a force of less than 30 pounds. A positive opening pressure is applied to the door when the handle is pushed down to open. The handle and lever arms, which apply clamping pressure, are adjustable as are the contact fingers. Single, double and vestibule door systems are available in most sizes and with a variety of options, including color-coordinated or wood-grained veneer finishes, view windows, access openings, ramps, locks, alarms, interlocks and microwave absorber seals. Flush floor systems are also optional. Optional auto latch door available.

Standard Construction

The basis of ETS-Lindgren's DEI construction is its unique patented design, which permits double shield enclosures to be assembled from individual panels. Panels are designed to accommodate a variety of shielding materials which are attached to a strong, non-conductive wood frame. When the shielding is overlapped and the panels bolted together, a resilient, as opposed to rigid, clamping pressure is applied, making it easier to achieve and maintain an RF tight seal. This design requires 45.72 cm (18 in) of space around the perimeter for assembly.

On midwall and ceiling panels, an angle bar clamping system is used that also provides additional structural support. Individual panels can be easily modified to accommodate accessories and special enclosure size requirements.

Inside Bolting Construction

This optional construction style enables the enclosure to be completely assembled from the inside, to accommodate areas with tight restrictions. This design employs separate clamping strips to interconnect panels. In other aspects, it is similar to standard construction and maintains the DEI principle.

Floor

Special care is taken to protect the inside floor shield by covering it with a layer of .953 cm (.375 in) plywood. A separate walking surface consists of.317 cm (.125 in) vinyl tile on 1.9 cm (.75 in) A-C plywood panels, which are interconnected with .317 cm (.125 in) aluminum strips, to ensure a flush, durable floor capable of supporting 453.59 kg (1,000 lb) per square foot. Floors can be strengthened to accommodate heavier loads when required.

| Physical Specifications | |||

| ?Large Panel Enclosures Sizes (Outside Dimensions) | |||

| ?Model | ?Height | ?Length | Width |

| ?8W ?? | 2.48 m (8.14 ft)? | 2.55 m (8.37 ft)? | 1.33 m (4.36 ft |

| ? ?22W | ?2.48 m (8.14 ft) | ?3.77 m (12.37 ft) | 4.99 m (16.37 ft) |

| ? ?30W | ?2.48 m (8.14 ft) | ??3.77 m (12.37 ft) | 7.44 m (24.41 ft |

| Electrical Specifications | |||

| Exterior Shield | Copper Screen | ||

| Interior Shield | Copper Screen | ||

| Magnetic (14 kHz) | 68 dB | ||

| Electric (14kHz) | 120 dB | ||

| Planewave 450 MHz | 110 to 120 dB | ||

| Planewave 1 GHz | 90 to 110 dB | ||

| Microwave 10 GHz | 50 to 80 dB | ||