Overview

Reasons to choose Vicreate Microwave

With the increasing improvement on properties of microwave absorber, polyurethane (PU) microwave absorber is incompetence on the chamber of some field, thus a kind of hard foam based microwave absorbing materials is deep studied, which includes expanded polyethene (EPE), expanded polystyrene (EPS), expanded polypropylene (EPP) and so on. These polymers have closed cell structure and are moisture-proof, non-deformation, whose mechanical strength is superior to PU materials. This new kind microwave absorber is produced with microwave absorbing agent added in raw materials process, then compression molded, so products with certain shape and properties are obtained. The whole manufacture process is mechanical so that the performance is stable.

Choose EPP as microwave absorbing matrix

Good thermo stability. EPE has the temperature resistance of 70-80?, EPS is less than 80?, while EPP can withstand over 120?. Moreover, EPP has less than 2% shrinkage at 120? over 22h. Good mechanical property. EPP with density of 0.035g/cm 3 has tensile strength of 0.56MPa and 0.38MPa at longitudinal direction and transverse direction, respectively. Good environmental friendly. Compare with PU, EPP doesn’t yield harmful isocyanate residue and the base material can be recyclable. Compare with EPS and EPE, EPP doesn’t use hydrochlorofluorocarbon (HCFC) or butane in foaming process, so that the material has no bad effect on environment after degradation.

Adopt full-wave band simulation

Traditional microwave absorber is designed by “transmission line” theory. In our work, products are designed by full-wave band simulation. After optimizing design, the best absorber structure can be obtained and assure the electromagnetic wave absorbing property of material.

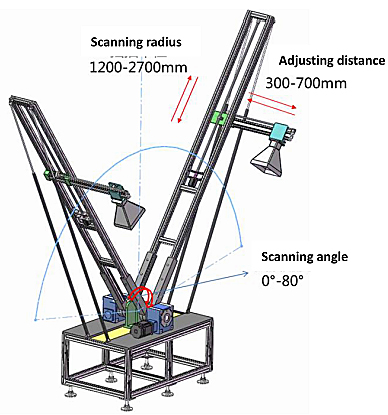

Adopt space scanning method to measure reflectivity

Traditional “Arch method” can measure the reflectivity in the range of 2-18GHz, beyond which the test precision will be lower. In our technology, microwave absorber measurement adopts new swing arms instrument that has the shape of number “7”, which works by space scanning. This method can cover a broad frequency band of 0.5GHz -70GHz and the scanning angle is multiple dimensions, thus the test precision is well improved.

Excellent properties

- Electric property: EPP has small dielectric constant and the surface reflection is low. The matrix is homogeneous, inside which there is enough electromagnetism attenuation. Therefore, the EPP absorber has good absorbing property in microwave band.

- Flame retardant property: UL94 HF-1.

- Limit oxygen index (LOI): >27%.

- Work temperature: long time at -50-100?, short time at 120?.

- Environmental friendliness: raw material is non-poisonous and odorless, no release of harmful gas.

- Finished products: Stable properties and meet RoHS.

- Physical performance: directly compression molding and accurate size; multiple colors and customization; stability and not easy to deform.

Wide applications

Property of EPP hard foam microwave absorber is verification in compact field chamber by RCS method, whose test quiet zone is bigger than 1.5m and the distance between absorber and antenna is over 10m, which meet distant field condition. EPP absorber can be used in various OTA test chamber and PIM chamber, and can provide a pure electromagnetic environment for the chambers.

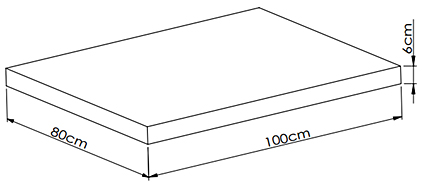

| Physical Specification | |

| Dimension | 100 x 80 cm |

| Thickness | 6 cm |

| Nominal weight | 3.3kg |

| Reflectivity at Normal Incidence | |

| 0.5 GHz | -7 dB |

| 1 GHz | -7 dB |

| 2 GHz | -9 dB |

| 4 GHz | -11 dB |

| 8 GHz | -14 dB |

| 18 GHz | -18 dB |

| 40 GHz | -22 dB |

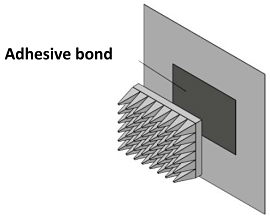

| Advised installation | |

| Adhesive bond | √ |

| Screw Fastening | |

| Adhesive and Screw | |

Series of Plate Absorbers

DURATM series of plate absorbers have good mechanical properties, which are suitable for loading or compression resistance parts. Plate absorbers have electromagnetic wave absorbing property and can be cut freely, which show grate prospect in building irregular corner or load-carrying parts.

| Reflectivity at Normal Incidence | |||||||

| Model | 0.5 GHz | 1 GHz | 2 GHz | 4 GHz | 8 GHz | 18 GHz | 40 GHz |

| VPL-30 | -6.5 dB | -13 dB | -9 dB | -12 dB | -18 dB | -21 dB | |

| VPL-60 | -7dB | -7dB | -9 dB | -11 dB | -14 dB | -18 dB | -22 dB |

| Physical Specification | |||

| Model | Dimension | Thickness | Nominal weight |

| VPL-30 | 100 cm × 80 cm | 3 cm | 1.8 kg |

| VPL-60 | 100 cm × 80 cm | 6 cm | 3.3kg |

| Physical performance | |||

| Density | 0.057 g/cm 3 | >Compression strength ?10%) | 171.5 KPa |

| Tensile strength | 578.2 KPa | >Compression strength ?25%? | 223.9 KPa |

| LOI | ?27% (GB/T 2406.2-2009) | Compression strength ?50%? | 02.1 KPa |

| Life time | 30 years | Compression strength ?75%? | 548.2 KPa |

Installation Guide

For VPP-200, VPP-230, VPC-300 and VPP-300, we suggest to use adhesive, for VPP-450?VPP-600, we suggest to use screw fastening. Besides, for absorbers used on ceiling and side wall of chamber, we suggest to use adhesive and screw at the same time.

| | |||||||

| | |||||||

Manufacture Process of Microwave Absorber

Manufacturing technique of EPP microwave absorber EPP foam absorber

is based on expandable polyprolyene matrix and designed by ohmic dissipation of carbon black (CB). CB is electric carbon material with nano size and high specific surface area. In our technology, EPP is the wave-transparent matrix and CB material is absorbing agent. By combination of these two, a kind of light, water-proof, moisture-proof, acid-base resistance, ageing resistant and size stable microwave absorber is produced.

Preparation of EPP particles with electric CB

Electric foaming EPP particles are prepared by “autoclave method” with clear CO 2 as foaming agent. First, mix the polyprolyene (PP) plastic particles with different assistants and add needed amount of CB, via pelletizer, the PP plastic particles melt and coalesce with CB, forming new composite particles with size 0.6-1.2mm. Second, put above composite particles, foaming agent, assistants into autoclave, stir. By controlling the pressure, time and temperature (commonly near the melting point about -2~4? of PP particles), foaming process is going. Finally, release the pressure quickly and pour out the particles, clean and dry, EPP with electric CB are prepared.

Molding process of EPP absorber

Foamed EPP particles are uniform in size and have stable properties. The compression molding as following:

Input: EPP particles are suctioned into stock bin by suction system, and weighed for storage for use.

Load pressure: Pre-pressing can improve the deformation caused by transportation and increase the stability of products after molding, too. The pre-pressing system conclude six steps, that is, venting, weighing, suction, setting parameters, starting, and discharging.

Molding: Mould is designed according to the shape of absorber, here the foam absorber is pyramid shape. Before molding, following steps should to be done to get best molding condition: fixing mould, adjusting mould, setting parameters, pre-heating, suction and discharging. In molding process, it includes: closing moulds, suction, steam heating, cooling and stabilization, demould.

Drying: The surface of products taken out from mould has vapor and the product inside contains residual water. So drying is needed to ensure stable dimension.

Post-process: Smooth the edges and corners, correct local deformation.

Quality testing: Measure the size, shape, and weight of products to pick out inferior-quality products.

Packing: Pack the products for safe.

Measurement of reflectivity

Limited to size, distant field condition, transmission loss and so on, traditional “Arch method” for measurement has narrow testing band (2-18GHz) and the measurement precision is normal.

Vicreate Microwave self-designed “7” shape reflectivity measurement system can do space scanning and adjust the measuring distance and angle flexibly. The system can realize achieve ultra-wide band measurement of 0.5GHz-70GHz by changing the testing antenna. Moreover, this system can test the absorber in multi-degree of freedom, so the measurement precision is highly improved.