Overview

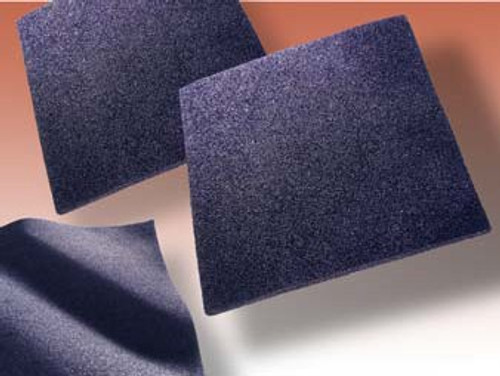

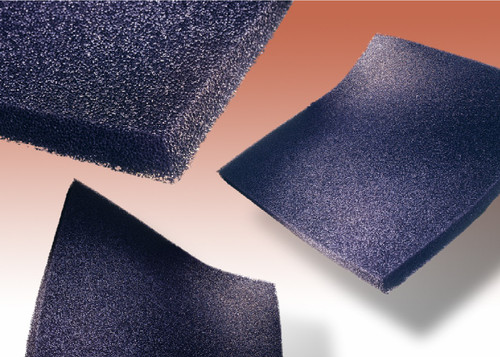

C-RAM MT is a series of flexible, lightweight lossy plastic foam sheet materials. A very broad frequency range of dielectric loss is achieved through carbon loading of the foam. C-RAM MT can be used to lower the Q of cavities, attenuate surface currents, absorb stray RF energy, isolate components and plug areas of RF leakage. It is a lossy load material; applications requiring a free space reduction of reflectivity should be addressed with C-RAM LF (see Technical Bulletin 320-1).

C-RAM MT is available in several grades with varying levels of carbon loading, and thus varying tangents. Each grade is available in a range of thicknesses. The material is a soft foam and is easily cut with a sharp knife. Cuming Corporation can also supply C-RAM MT with a peel-and-stick backing, and can die-cut or machine parts to specifications.

C-RAM MT-FR is a fire retardant grade. C-RAM MT is treated with fire retardant additives during its manufacturing cycle. C-RAM MT-FR meets UL-94-HF-2 requirements.

| TYPICAL PROPERTIES | |

| Color | Black |

| Density (dependent upon grade) | .06 to .13 g/cm3 (4 to 8 lb/ft3) |

| Service temperature | -50 to +120°C (-85 to +250°F) |

| Tensile strength | 12 psi |

| Elongation, min. | 150% |

| Tear Strength | 1.5lb/inch |

| Compression set, 80% | 5% |

| Compression set, 90% | 10% |

| Resiliency | 45% |

| Insertion loss | see table below |

METHOD OF APPLICATION

C-RAM MT can be readily cut with a sharp knife or a steel rule die to intricate shapes.

The normal method of applying C-RAM MT to a substrate is with a neoprene contact adhesive. For best results, the adhesive is brushed or rolled onto the substrate and allowed to dry tack-free (at least one hour). Adhesive is then applied to the back of the C-RAM MT, and when the adhesive is still tacky but no longer wet (usually about 2-3 minutes), the part is pressed against the coated substrate for an immediate and permanent bond.

Cuming Microwave offers Cambond 808, a solvent-based, non-flammable, neoprene contact adhesive for applying C-RAM MT (see Technical Bulletin 230-5).

As an alternative, C-RAM MT can be supplied with pressure sensitive adhesive (PSA), which is not a contact adhesive, but will provide an adequate bond in most applications, since the material is quite lightweight. Simply peel off the backing, and press the part firmly to a clean surface. The PSA will adhere with high tack to metals, wood, and many plastic surfaces.

| TABLE OF INSERTION LOSS AND ATTENUATION | ||||

| GRADE | INSERTION LOSS. dB/cm (dB/inch) | ATTENUATION, dB/cm (dB/inch) | ||

| 1 GHz | 3 GHz | 10 GHz | 3GHz | |

| MT-14 | 0.2 (0.5) | 0.4 (1.0) | 0.9 (2.2 | 0.4 (1.0) |

| MT-16 | 0.7 (1.8) | 1.5 (3.8) | 2.0 (5~0) | 1.4 (3.5) |

| MT-18 | 0.9 (2.3) | 1.8 (4.0) | 2.8 (7.0) | 1.5 (3.7) |

| MT-20 | 1.8 (4.5) | 3.2 (8.0) | 5.1 (13.0) | 3.0 (7.5) |

| MT-22 | 2.2 (5.5) | 3.9 (10.0) | 6.3 (16) | 3.7 (9.5) |

| MT-24 | 3.5 (14) | 11 (32) | 24 (60) | 11 (27) |

| MT-26 | 4.9 (19) | 16 (46) | 34 (89) | 16 (39) |

| MT-30 | 16 (40) | 24 (60) | 43 (110) | 19 (49) |

NOTE: Insertion loss measurements include the effects of surface reflections; the above values are close to, but not exactly, linear with thickness. For example, a ¼ inch thick piece has somewhat more than 1/4th as much insertion loss as a one inch thick piece.

Attenuation is a measure of loss within a homogeneous material, and does not take into account any reflections at interfaces. It is independent of thickness. This is a calculated, not measured, value.

AVAILABILITY

All grades of C-RAM MT are available in several standard thicknesses—

.125” (3.2mm)

.250” (6.4 mm)

.375” (9.5 mm)

.500” (12.7mm)

.750” (19.1 mm)

1.000” (254 mm)

Standard dimensions for all grades are flat sheets 610 x 610 mm (24 x 24 in). Specify the part as C-RAM MT-xx, where xx is the grade, followed by the thickness in inches (.125, .250, .375, .500, .750, 1.000).

We can supply other dimensions, and can diecut or machine parts to your drawings. It is possible to supply large and thick parts with a waterproof coating for outdoor uses. Consult Cuming Microwave for more details.

C-RAM MT can also be supplied with a peeland-stick pressure sensitive adhesive backing (specify by adding a /PSA suffix to the part name). This eliminates the need to work with liquid adhesive systems.

Normal color of the material is black, although it can be supplied painted blue as well.