Overview

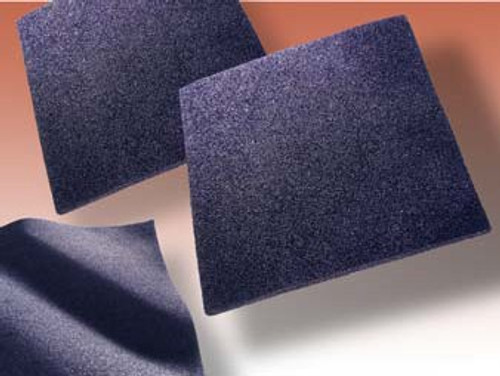

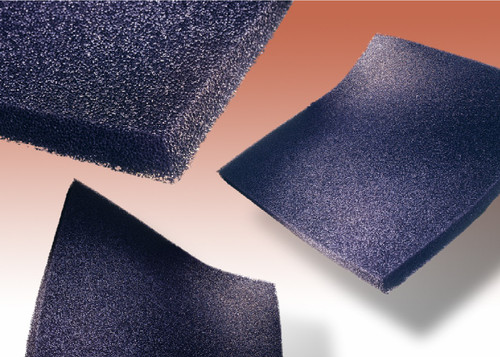

The C-RAM Corner Block is a carbon loaded urethane foam material used to fit anechoic chamber materials, such as C-RAM SFC, into the corners and edges of the chamber. These products meet all of the fire retardancy requirements of NRL Specification 8093.

TYPICAL PROPERTIES

C-RAM Corner Block is made of the same material as the pyramidal absorber it is being used with. It will have the same density and impedance as the C-RAM SFC foam.

The product is black throughout, and generally is sprayed with a light blue surface coating, both for cleanliness and to provide better light reflection inside a chamber. The absorber can be left unpainted if requested.

AVAILABILITY

C-RAM Corner Block is custom made to each anechoic chamber job, and is available in almost any dimension. Cuming Microwave engineers can help you specify materials for a chamber application, and can recommend specific configurations of corner blocks.

Generally, the block is as thick as the base of the absorber piece butted next to it, and as wide as the height of the absorber facing it. For example, a 3 in x 18 in x 24 in piece would be used when blocking SFC-18’s in a corner.

METHOD OF APPLICATION

C-RAM Corner Block is applied to chamber walls just as the C-RAM SFC pyramidal absorber would be. It is generally bonded in place with a neoprene contact adhesive, or it can be supplied with Velcro pile backing to attach to strips of Velcro hook bonded to the walls. Edges and corners of the chamber are generally blocked out first, then the C-RAM SFC pieces are fit from the floor up to the ceiling. Corner Block is readily cut with a sharp knife, or, preferably, using a bandsaw or electric carving knife.